-

WD 430: Flow monitoring system

This clip shows the WD 430 Flow Monitoring System.

After use, the endoscope channels are contaminated with blood and residue. Water, augmented with detergents and disinfecants, is pumped through the channels to clean them. When a channel is blocked, the monitoring system registers the blockage, stops the machine and indicates which channels require manual inspection.

For the visualization, the monitoring sensors are shown as manometer-type analogue displays. In the machine itself the measurements are captured and processed digitally.

A separate pump and rotary spraying system is used to clean the outside of the instruments.

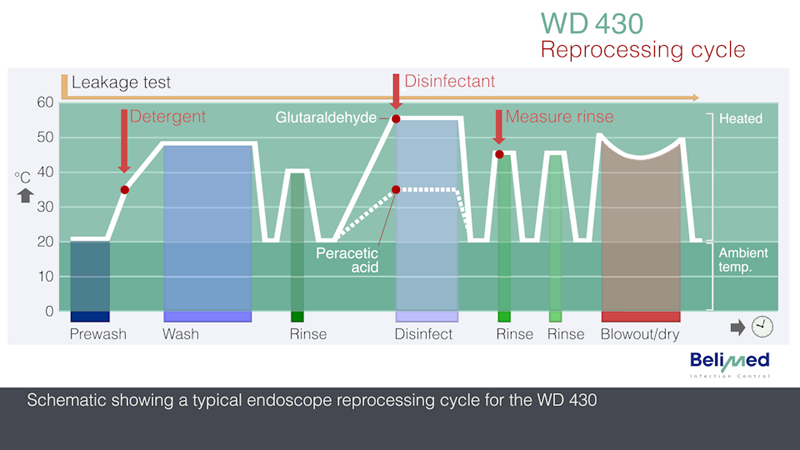

For simplicity, the clip shows a simple start and stop cycle of the pump. The full wash process runs through a series of wash-and-rinse cycles in which precise mixtures of detergent and disinfection agents are added to the water.

A heating system heats and regulates the washing and rinsing solutions at precise temperature levels.

The chart below shows a typical reprocessing cycle. The white line shows the rise and fall in the temperature of the washing solutions. Column-widths show the duration of the washing, rinsing and drying operations. Space between columns shows the heating and cooling periods.